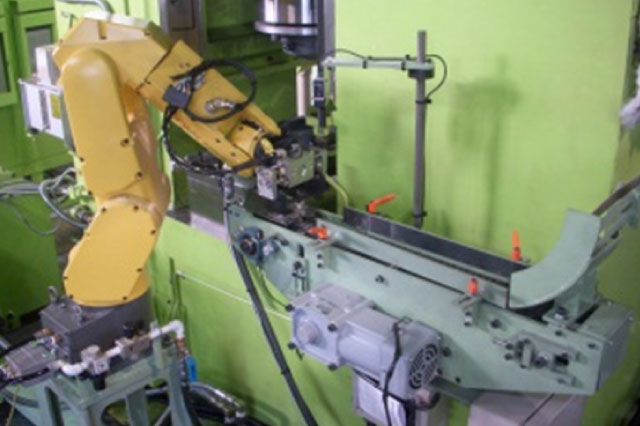

Ancillary equipment

We have also recorded numerous achievements using automated equipment, cultivated based on abundant accumulated expertise from the rotary hearth furnaces produced to date. The processes before and after forming include cutting/material feed/forging/mold release agent application/trimming/cooling/ thermal treatment etc., and many other interim conveyance processes. For unmanned operation, we have actively devised an inlining facility. We also handle program teaching such as robots, etc. in-house, to provide you with total support, including interim conveyance processes.

Press loader

-

Hexaxial multijoint Robot type

-

Rotary type

Mold release agent injection system

-

Linear

Mold preheat burner

-

Round shape

-

Square shape