Furnaces for copper alloys

The ROTAVECT BRC series, perfect for heating copper alloys, offers tremendous advantages. Some of these include our core rapid heat transfer concept, which harnesses circulating hot air technology; maximizing uniform temperature distribution and achieving seamless energy-saving, etc., all on an unrivaled scale. With our consistent circulating hot air technology developed over 30 years as a cornerstone, we have constantly striven to further study and develop our products, with a record of over 1,000 units already delivered to date. The furnace, which consists of a single burner and is based around a proper circulating hot air system, outperforms units with multiple burners in every way.

Forging heating furnace

[Main items to process] parts for optical machinery and appliances, automobile-related parts, water faucet parts, sanitary equipment parts, gas appliance parts, luminaire parts

-

R-type rotary hearth furnace Forging heating furnace

ROTAVECT R60-72

Ring/flat forging stock

-

DHF-type rotary hearth furnace Forging heating furnace

ROTAVECT DHF94-54-2

Round bar forging stock

-

RF-type rotary hearth furnace Forging heating furnace

ROTAVECT RF90-9

General-purpose type for flat/round bar/atypical material heating, secondary heating, etc.

-

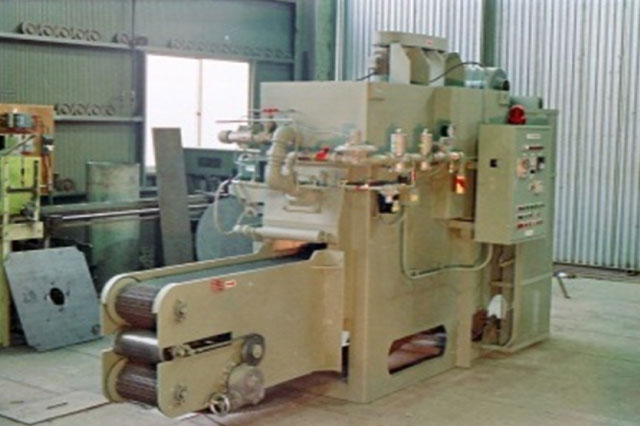

Mesh belt continuous BRC-type Forging heating furnace

BRC-M/1/2/3/4

General-purpose type for flat/round bar/atypical material heating, secondary heating, etc.

Heat treatment furnace

-

Roller hearth

RH type Annealing furnaceRH10

For forging/coil/rod/tube/wire

-

Mesh belt continuous

BRC-type Annealing furnaceBRC-OD

For forging

-

Batch RB type

Annealing furnaceRB

For forging/coil

Billet preheating furnace

-

Rolling intern continuous

RI type Billet preheating furnaceRI12

Extrusion billet for heating