Automation Equipment

We will design and deliver custom-made automated production lines, including industrial furnaces, to meet the customer's target values and fit the space in the factory.

We have a track record of delivering the following automated equipment:

1. Copper alloy automatic forging equipment

[Equipment configuration] Heating furnace, charging conveyor, extraction conveyor, press loader, press unloader, press machine, release agent device.

Material supply → heating → forging are all carried out automatically.

We also have a full lineup of supply devices designed to suit the workpiece shape.

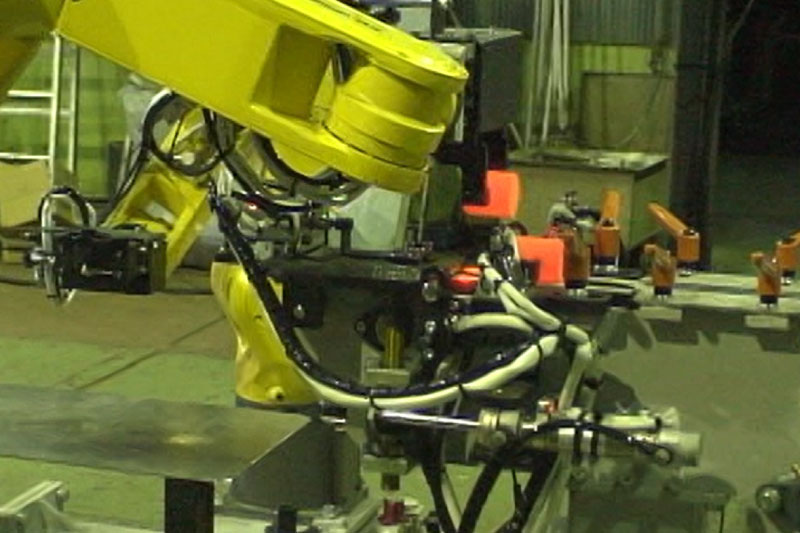

2. Automatic conveying equipment for aluminum wheel flow forming machine

[Equipment configuration] Heating furnace, carrying conveyor, disk surface cooling water tank, transport robot, molding machine, carrying conveyor

Heated wheels are automatically transported to the rim molding machine for aluminum wheels for automobiles.

We can propose layouts etc. after considering the operating range etc.

3. Aluminum alloy automatic forging before heating furnace transportation

[Equipment configuration] Heating furnace, alignment conveyor, loading robot, unloading robot, press robot, press machine

Five pieces are loaded into the heating furnace loading side at the same time, and the unloading side takes them out one by one and passes them to the press robot.

4. Automatic transport using a vision system

New product! The robot uses vision to recognize the workpiece coming out of the continuous furnace. It can approach the workpiece in any position.

[Features] (1) No positioning mechanism required (2) No teaching required

We also have a test machine, so why not give it a try?

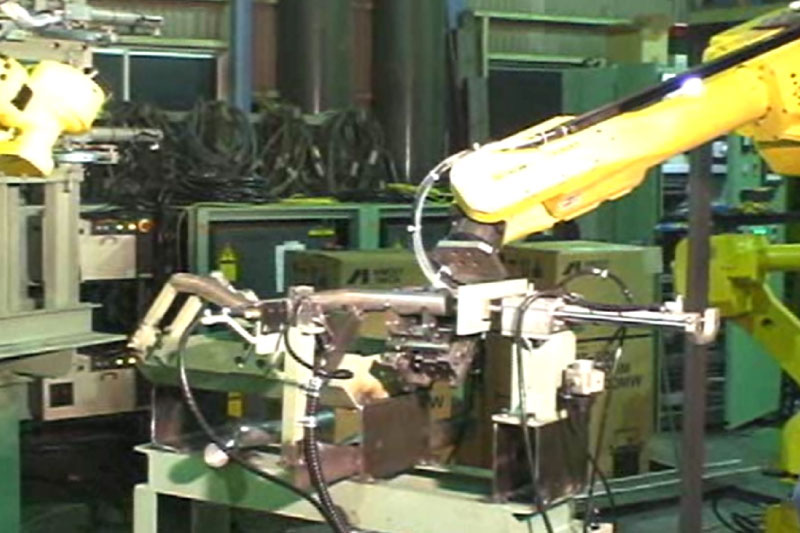

5. Aluminum alloy suspension arm automatic forging equipment

[Equipment configuration] Heating furnace, heating furnace robot, positioning table, rough mold setting robot, finishing transfer robot, release agent robot, press machine

The entire process of heating aluminum round bars → positioning → press loading → forging → removal → release agent application is automated.

6. Aluminum alloy engine piston automatic transfer

[Equipment configuration] Storage container, de-stack robot, weight judgment table, alignment and elevating device

The robot de-stacks the workpieces aligned in the container one by one, places them on the weighing turntable, judges whether they are OK or NG, and supplies them to the heating furnace.

Aluminum alloy engine piston automatic transport

We provide production lines that will help you achieve your goals.

Unique Factory Automation

We do not only provide industrial furnaces. "Produce each product in XX seconds." We will share the target values that our customers want to achieve, and design and deliver an automated production line that includes an industrial furnace that can achieve those targets...

Read more >>

For inquiries about automation equipment...

- hiro【$】furnace-juko.co.jp* Please send us an email by replacing 【$】 with @

- Person in charge

- Sakamoto (Oita Factory Sales manager)

- Phone number

- 0974-63-0004(代)